Glass Section

“Our Glass department is providing now a full Range of glass fabrication and related works; we have well equipped machineries, we have our own Tempering plant, Lamination plant. We have a warehouse with huge capacity of glass storage and mainly dealing directly with international and national glass manufactures &suppliers like saint gobain, Guardian glass, AGC glass, intraco, emirate glass... we fabricates glass into Double glazing,framelessglass,laminated,polished,beveledglass, design sandblasting, all mirror related works and so much more.. This all items served for your building with full Quality and attractive price”.

OUR PRODUCTS RANGE

- Double glaze glass (Insulated glass)

- Polished single glass

- Laminated glass

- Double glazed with lamination

- Frosted glass

- Design glass

- Back painted glass

- Mirror

Double Glazing

Double glazing compared to single glazing, cuts heat loss in half due to the insulating air space between glass layers, the inner and outer layers of glass are both clear and separated by an air gap.in addition to reducing the heat flow, a double glazed unit with clear glass will allow the transmission of high visible light and high solar heat gain.We Suntech provides high performance Low-E coating double glazing for reduced solar heat.

A double-glazed unit with high performance tinted glass reduces solar heat gain and also has a visible transmittance closer to clear glass. Thought the tint has no effect on the U-factor but reduces solar gain, which is a benefit in the summer.

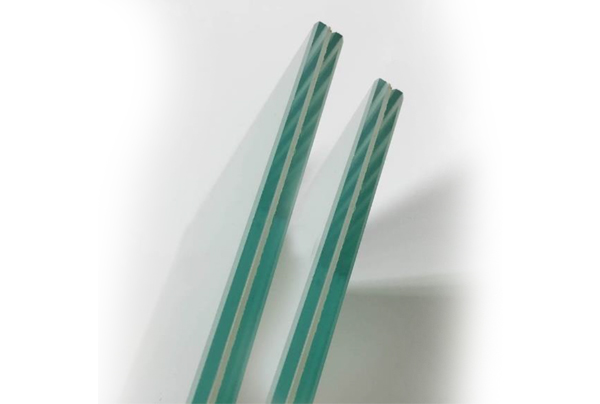

Laminated Glass

This type of glazing consists of two or more lites of glass and one or more bonding interlayer. Glass does not shatter and is the logical choice for a safety glazing, due to its break” safe” characteristics, laminated glazing resists condensation twice as long as clear glass and provides high energy efficiency results. The use of laminated in glass in hurricane prone areas can also reduce the effects of windstorms on building by preserving the integrity of the building envelope and by preventing glass particle fallout.

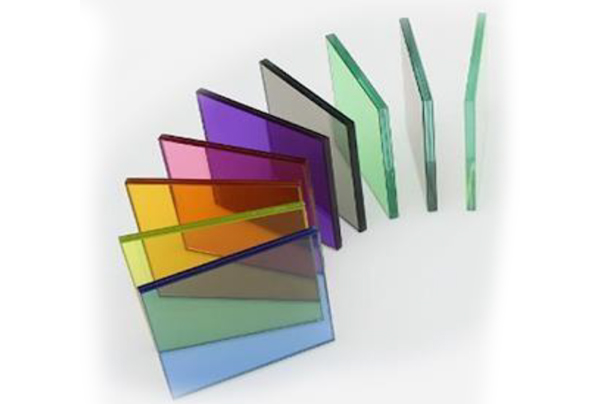

Tinted glass

Tinted or Heat Absorbing glass is made by adding various colorants to the normal, clear glass batch to create a desired color. The typical colors produced domestically include bronze, gray, dark grey,aquamarine, green,deep green,blue,deep blue and black.Visible lighttransmittancewill vary from 14%to 85% depending on the color and thickness.The color density is also a functionofthickness. As the thickness increases,visible light transmittance will decrease.Tinting increase the solar transmittance of glass and increases solar heat absorption. Because of this heat buildup, heat treating is sometimes required for tinted glass.

Reflecting Glass

As the demand for better performing glass products increased, flat glass products are coated with one or more coatings of inorganic materials to enhance its thermal and optical performance characteristics (solar factor, emissivity, colour, light transmission, light reflection).

Our Glass Suppliers

| MANUFACTURER | COUNTRY |

|---|---|

|

Europe |

|

Europe |

|

USA |

| MANUFACTURER | COUNTRY |

|---|---|

|

USA |

|

Belgium |

|

U.A.E |

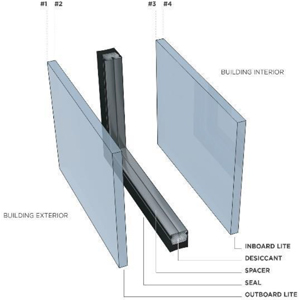

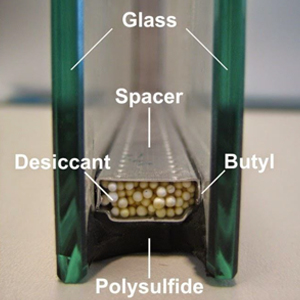

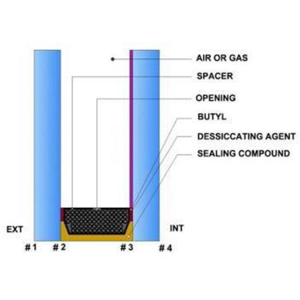

Primary Sealant

The Inner or the primary sealant being used polyisobutylene (commonly called butyl). the butyl controls the moisture vapor transmission rate into the IG unit. During processing, it’s also the primary sealant(butyl) which holds the unit firmly while secondary sealant is applied.

Secondary Sealant

The secondary sealant is responsible in holding the unit firmly together during its service life which is why it is very important to ensure that the sealant has an excellent adhesion to the glass and to the spacer frame.

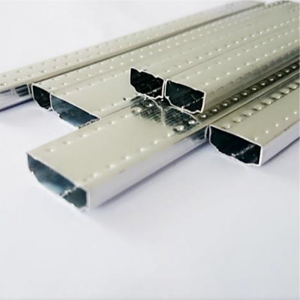

Spacer bar

The spacer bar is used to provide an airspace between the glasses. The common thickness of IG spacers readily available for production are; 6mm, 8mm, 10mm, 12mm, 14mm, 16mm, 18mm, 19mm, 20mm, 22mm, and 24 mm.Other thickness is also available up on request. Spacer bar types being used in the factory are normal mill finished, black anodized, stainless steel, warm edge.

Desiccant

Desiccant plays an important role in an insulated glass unit, during manufacture, a volume of air istrapped inside the IG Unit at a certain temperature and relative humidity. The moisture content of the trapped air will condense when the temperature was dropped therefore the Desiccant is needed to dry the airspace. The main function of the desiccant is to absorb the moisture that permeates through the seal.